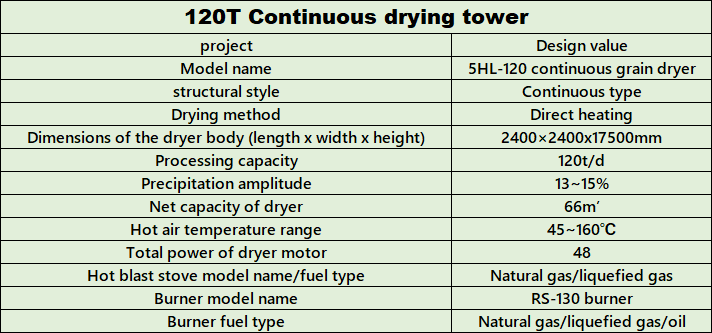

120T Continuous drying tower

- Category: Grain dryer

- Product description:

|The product advantages are applicable to various crops such as wheat, corn, rice, soybeans, sorghum, buckwheat, etc.

The body is made of galvanized sheet material, with a sturdy structure, low failure rate, and long service life.

A hot blast stove that uses coal, oil, natural gas, straw, rice husk, and other fuels as its heat source, or steam as its heat source.

The drying tower uses hot air as the heat medium to dry grains.

Its interior is mainly composed of an intake ventilation joint and a corner shaped ventilation box. The corner shaped box is filled with grains,

which flow from top to bottom. Hot air enters through the intake ventilation joint and passes through the grain layer downwards. The exhaust

gas is discharged through the exhaust corner shaped box. The flow of hot air and grain in the same direction is called co current flow. When

hot air passes through the grain layer, it transfers heat and moisture to the grains: the hot air transfers heat to the grains, causing their

temperature to rise. The grains are heated and the moisture evaporates into the air, becoming exhaust gas.

The dried hot grain flows down to the slow drying section, where the temperature and moisture of the inner and outer layers of the grain

tend to balance, achieving uniform precipitation. After the grain is softened, it enters the cooling section, where it is cooled to the storage

temperature before being discharged from the grain discharge section.

(1) Processing varieties: corn, rice, wheat, sorghum.

(2) Single machine model batch: daily/(24-hour) drying capacity>100-120 tons/unit.

(3) Heating method: direct heating method.

(4) Working mode: automatic computer control, batch low-temperature circulation drying.

(5) Structural setting: equipped with a dry layer and a gentle layer

(6) Feeding time: ≤ 60 minutes (single machine).

(7) Grain discharge time: S60 minutes (single machine).

(8) Precipitation rate: 1-1.5%/hour.

(9) Unit precipitation energy consumption: 12.21 million kcal/h 70 liters of fuel oil.

(10) After drying, the waist burst rate is less than 0.8% for the entire system

(11) Uneven moisture content of grains exiting the machine: S1% (when the moisture content uniformity of grains entering the machine is less than 3%).

(12) Outbound grain temperature:

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: HASSAN

phone:+8618603722872

Whatsapp:+8618569929372

Email:[email protected]

Add:Wenfeng District, Anyang City, Henan Province, China